Sales & Operations Planning & Theory of Constraints

- Real Throughput

- Jun 29, 2022

- 5 min read

Updated: Dec 27, 2022

How to move from an approach aimed at producing a viable plan to one fostering for the full exploitation of resources for improving profits.

There are many interpretations regarding the Sales & Operations Planning process and how it is implemented within organizations. The objective of this article is to explain its purpose, debate the most common mistakes, and propose a way to get better results from the process.

We will discuss:

The definition of the Sales & Operations Planning and its purpose

The undesirable effects caused by wrong paradigms and process set-up

How to improve the process and its results with the aid of the Theory of Constraints

To read the full article, download it free from the download center.

1. The S&OP process and its goal

The Sales & Operations Planning (S&OP) process is defined by APICS as

“A process for developing tactical plans that provide management with the ability to strategically direct its activities to achieve competitive advantage on an ongoing basis by integrating customer-focused marketing plans for new and existing products with supply chain management. The process brings together all of the company's plans (sales, marketing, development, production, procurement, and finance) into a single integrated set of plans (APICS Dictionary)

Looking at its definition, the S&OP process aims at linking operational plans in the direction of the strategic goal of the organization, whose economic and financial representation is summarized in the business plan.

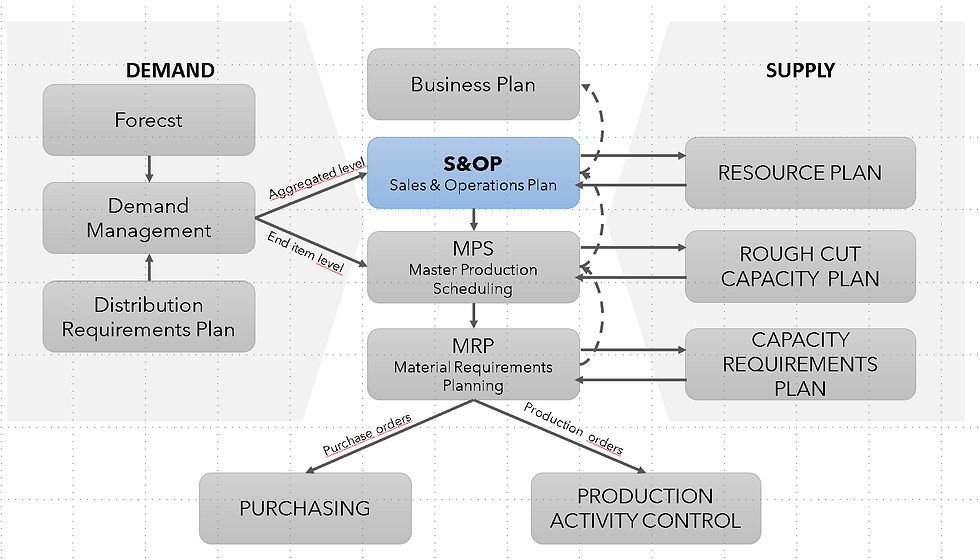

The Sales & Operations Plan is the first step of a broader operational planning cycle - called Manufacturing Planning & Control (MPC) - which, as we move from the more aggregate levels down to the particulars, is broken down into several detailed steps until the issuance of supply orders.

Below we summarize the different steps defining the MPC cycle, highlighting the links between the various stages and the positioning of the S&OP process, according to the APICS representation.

Many authors agree that the goal of the Sales & Operations Planning process is to produce a "Viable Production Plan" i.e., a plan of product families and volumes that is technically feasible according to the capacity available.

Let’s move our steps saying that we disagree with such point of view as it limits the goal of the S&OP process to the achievement of just a viable plan, leading the organization to important waste of its full potential.

2. The most common mistakes found in several S&OP process set-up

There are many mistakes that are commonly made in setting up and executing S&OP process, but let's start right away by saying that the most negative and limiting one happens when its goal is narrowed to the purpose of "achieving just a VIABLE PLAN"

In many years of consulting, we can claim to have "seen it all," but if we were called upon to rank the top 3 of the most common mistakes that are made when setting up and executing the Sales & Operations Planning process, we have no doubt:

Limiting the purpose of the process to the definition of a Viable Plan, an excessive focus on the "technical" feasibility of the plan, neglecting the purpose of the strategic objectives

Lack of adequate and consistent metrics to compare the impacts of different scenarios for making the best decisions

Falling in love with details, losing the big picture, and confusing the purpose of the different stages of the planning cycle, creating hybrid solutions that are neither effective for making strategic decisions nor for setting operational plans.

2.1 Limiting the goal to the definition of a Viable Plan

When defining and organizing the S&OP process, its objectives, inputs, roles, tools, and levels of detail, we shall not forget that the S&OP is a tactical plan of actions NECESSARY AND SUFFICIENT to achieve the strategic objectives.

Too often, the implications of the above statements are undoubtedly not clear. When asking to S&OP process owners their opinion about the purposes of the process, we have often picked up statements such as::

The purpose is to meet the demand requirements of the internal customer (ed: the functions that preside over the markets)

The goal is to maximize efficiency in manufacturing operations

The goal is to keep inventory as low as possible

The goal is to balance demand and supply to minimize nervousness in the operations.

And other similar variants, all statements that are clear symptoms that management is getting satisfied when they achieve the Viable Plan as defined above, focusing on its technical feasibility and on their own local goals, while neglecting the real goal of maximizing the achievement of the strategic goal. This phenomenon is a consequence of several problems:

Poor definition/understanding of the goal and strategy of the organization: unclear what the destination is.

Poor definition of roles and/or process: the helmsman is missing and/or the team does not know exactly what they are called upon to do

Management, pushed by local performance metrics, goes in different directions to preserve their own local objectives, rather than converging on the action plan to meet the global goal: lacks a clear roadmap

Lack of basic knowledge of the process and its implications and lack of clear decision-making processes and rules: priorities not defined.

Another important factor, which drives management to settle for a Viable Plan, are paradigms and the impact they have on human’s behavior. One of those paradigms, which exerts a very strong restraining force, are the budgets.

In the glossary of the Theory of Constraints, the main goal of managerial action is to pursue the highest level of "exploitation of the system's constraint": we can translate the term exploitation as "getting the maximum possible value from the weakest link of the system".

Budgets, with their predetermined and deterministic objectives, from being an "ex-ante coordination tool," risks being, often, an "ex-post deterrent mechanism." It tends to generate in managers the so-called "baker's syndrome": being happy of a “sold-out” at 5 p.m., neglecting the revenue opportunities from being out of stock from 5 p.m. onward.

Returning to the real goal of the S&OP process - making the tactical decisions that are necessary and sufficient to achieve the strategic goal - a clear definition of the metrics to be met is fundamental, and this brings us to the second most common mistake

Free download the full article to continue reading:

The other most common mistakes

The undesirable effects caused by poor process set-up and wrong paradigms

How to improve process and results with the Theory of Constraints

Conclusions

A well-crafted S&OP process can actually be a source of competitive advantage. The principles of the Theory of Constraints enable significant improvements to the process, metrics and its focus on strategy.

CONTACT US TO FIND OUT MORE:

At Real Throughput, with over 30 years of experience in Theory of Constraints, Lean and Six Sigma, APICS and Supply Chain best practices, we have the know-how and experience to define the best solutions to implement an effective and successful S&OP process, starting with strategies and ending with information systems to support simulation and decision-making processes.

For info:

© 2022 – Real Throughput – All Rights reserved

Comments